Welcome to outsourcing broker

We connect Leading Contract Manufacturing Companies in Europe & Asia

Benefits of Outsourcing to an International Contract Manufacturer

Cost Savings

One of the most compelling reasons companies choose international contract manufacturing is the potential for substantial cost reductions. Lower wage structures in selected regions can significantly decrease overall production expenses. In addition, outsourcing allows companies to avoid or reduce indirect costs such as facility upkeep, energy consumption, machinery purchases, and long-term capital investments, as these obligations are assumed by the contract manufacturer.

Access to Specialized Expertise

International contract manufacturers often focus on specific industries, production techniques, or technologies. Partnering with such specialists gives businesses direct access to advanced technical know-how and proven manufacturing experience. Moreover, global manufacturing partners frequently invest in modern production methods and innovative technologies, enabling companies to benefit from state-of-the-art solutions that may be costly or impractical to implement in-house.

Focus on Core Competencies

- Outsourcing production activities allows companies to concentrate on what they do best. By transferring manufacturing responsibilities to an external partner, organizations can dedicate greater attention to strategic priorities such as research and development, branding, sales, and customer relationships. This targeted allocation of internal resources often results in stronger operational focus and improved overall performance.

Risk Mitigation

International contract manufacturers typically operate diversified production networks and maintain relationships with multiple suppliers. This geographic and operational spread helps reduce exposure to supply chain interruptions caused by natural disasters, political instability, or market volatility. Additionally, experienced global manufacturers are well-versed in international regulatory standards and compliance requirements, helping businesses manage legal and regulatory risks more effectively.

Time-to-Market

- Global contract manufacturers can significantly shorten production timelines. Their established infrastructure and optimized processes often enable faster manufacturing cycles, allowing products to reach the market more quickly. Many international partners also offer rapid prototyping and agile development capabilities, supporting quicker design validation and product refinement.

Economies of Scale

- Higher production volumes achieved through outsourcing can unlock economies of scale. By producing larger quantities, manufacturers can reduce per-unit costs, benefiting from bulk purchasing of materials and more efficient use of production capacity.

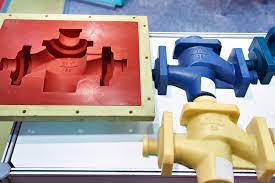

Contract manufacturing is a form of outsourcing where a company hires another company to manufacture its products. This can encompass a wide range of services, including:

- Component production

- Assembly

- Assembly

Contract Manufacturing Industry Groups

Why Contract Manufacturing

Many businesses rely on contract manufacturing as a strategic tool to reduce operating expenses, improve the efficiency of internal resources, and avoid significant capital investments in expensive production equipment.

Contract manufacturers typically provide a broad spectrum of services, including contract machining, outsourced assembly operations, and specialized subcontracting solutions tailored to specific production requirements.

Their technical capabilities span a wide range of manufacturing processes, from conventional methods such as drilling, turning, boring, milling, sawing, tapping, and planing to advanced and non-traditional technologies. Increasingly, contract manufacturers are integrating innovative processes such as electrical discharge machining, electrochemical machining, ultrasonic machining, and other high-precision techniques to meet complex and evolving production demands.

Our capabilities

For the consumer products industry we can provide in European & Asian markets

Manufacturers

Identification

Transparent pricing, we charge a flat service fee

Negotiations & Contracting

Tooling, Prototyping & Sampling

Manufacturing Management

QC / QA

Pre-shipment Inspection

Logistics & Shipping

Things to Consider

- Before entering into a contractual relationship with a contract manufacturer, it is essential to conduct a comprehensive evaluation of several critical criteria. These include the manufacturer’s access to modern technologies, technical and production capabilities, adherence to your quality and specification standards, logistics and delivery options, estimated production and shipping timelines, availability of flexible payment terms, market reputation, and overall experience within the industry. If a manufacturer is unable to meet your required production schedule or delivery deadlines, it is advisable to continue the search for a partner better aligned with your expectations.

- Equally important is the manufacturer’s willingness to engage in a trial phase prior to finalizing a long-term agreement. Hesitation or refusal to participate in a trial period may signal limited transparency or operational confidence. Similarly, reluctance to discuss payment structures, customization options, or quality guarantees should be regarded as potential red flags.

- Reputable contract manufacturers actively seek to demonstrate their reliability and long-term partnership potential. They are transparent about their internal processes, clearly communicate their organizational structure, and are capable of tracking and managing customer orders effectively. When a prospective partner fails to clearly demonstrate these capabilities, a cautious approach is warranted, and alternative providers should be considered. Working with unreliable manufacturers carries significant risks, including inconsistent product quality and service delivery. More critically, sharing proprietary designs, technologies, or production specifications with an untrustworthy partner may expose your business to intellectual property risks.

- While global connectivity has simplified the marketing, sourcing, and management of manufacturing partnerships, identifying truly dependable contract manufacturers remains a complex task. To support this process, we have compiled a curated selection of contract manufacturers known for their performance and reliability. Detailed information on these providers is presented below. For optimal results, we recommend evaluating their strengths, narrowing the list to three or four suitable candidates, and initiating direct discussions with each. After comparing their proposals and capabilities, you can select the partner that best matches your operational needs and proceed with contract negotiations.